Coal Grinding Vertical Spindle Mill Vibration Cause

تطبيق المنتجات

Vibration Vertical Mill Crusher, Grinding Mills

Standalone Vertical Roller Mills without Hot Gas, LOESCHE ROLLER MILL VIBRATION,INTERNATIONAL CEMENT REVIEW JUNE 2011 For vertical roller mills (VRM), water injection on the grinding table is a common way to stabilise the grinding bed and gives a smoother mill operation with lower vibration levels However,,.Unstable vibration .

(PDF) DRY PROCESSING OF 4 mm COAL FINES

DRY PROCESSING OF 4 mm COAL FINES THROUGH AIR JIG and AERODYNAMIC SEPARATOR. mm runofmine coals. Deck vibration consumption and abrasion of grinding media of vertical spindle

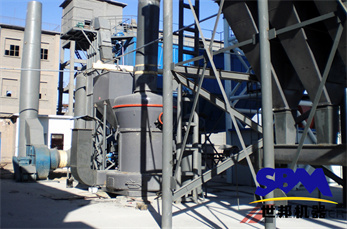

Raymond Mill,Raymond Mill Working Principle

raymond mill structure and working principle. The whole structure of Raymond mill is composed of a host machine, analysis, plumbing, air blower, finished cyclone separator, jaw crusher, bucket elevator, electromagnetic vibration feeder, electric motors and other host is composed of a frame, Raymond mill inlet volute, blade, grinding, grinding ring, a cover casing and a motor.

Product

Calcite Grinding Mill. Vibration stop phenomenon of Calcite Grinding Mill1. Case of LM Vertical Mill reducerThe cement grinding system of a certain company is the combined grinding system of CKP240 LM Vertical Mill + ball mill. Coal Grinding Mill.

How to reduce vibration in milling

Milling vibration can arise due to limitations in the cutting tool, the holding tool, the machine, the workpiece or the fixture. Explore our strategies on how to reduce vibration in milling operations.

Coal Pulverizer Maintenance Improves Boiler

Optimized coal pulverizer performance is a prerequisite for furnace combustion efficacy. Here are some solutions for overcoming common combustion problems.

MB5X Pendulum Roller Grinding Mill

The spindle of MB5X pendulum roller grinding mill adopts dilute oil selflubricating system, which is fully automatic and laborsaving. Spindle bearings and transmission shaft bearings are selfcontained oil pump circulating oil supply lubrication, and no manual operation is needed to effectively ensure the stability of the main engine operation.

FOR VERTICAL ROLLER MILLS Loesche

FOR VERTICAL ROLLER MILLS by Matthias Authenrieth, Thomas Hyttrek and Andreas Reintke, Loesche , Germany, and Steven McGarel, Senior Consultant, USA LMmaster_ 1

A Brief Tutorial on Machine Vibration

A Brief Tutorial on Machine Vibration by Victor Wowk, Machine Dynamics, Inc. The purpose of this tutorial is to provide sufficient knowledge to understand machine vibration diagnosis. You may be tasked with solving a vibration problem, or you may be overseeing someone else and you need to understand the process.

BEARING FAILURE: CAUSES AND CURES

vibration. A small relative motion between balls and raceway occurs in nonrotating ball bearings that are subject to external vibration. When the bearing isn''t turning, an oil film cannot be formed to prevent ~rina~ ~mks raceway wear. Wear debris oxidizes and accelerates the wear process. Correct by isolating bearings from external vibration, and

SCM Ultrafine Mill Ore Milling

SCM Ultrafine mill is an ideal largescale grinding equipment, combined with ultrafine crushing technology, set broken, dry, grinding, grading conveying in one, high production efficiency. The Superfine mill can grind the bulk, granular and powdery materials into the required powdery materials.

Raymond Vertical Spindle Coal Mill | Crusher

raymond vertical spindle coal mill replacement segments. vertical coal mill pulverizer [crusher and mill] Medium speed pulverisers are typically vertical spindle mills that grind the coal between rollers or balls and a coal mills are of ball and race design or Raymond vertical spindle to coal pipes causing poor fuel

shanghai clirik machinery feldspar grinding mill

feldspar vertical mill cement mill wear parts roller tyre,grinding ring Highchromium wearresistant roll sleeves are widely used in largescale materials such as metallurgy, electric power, cement, chemical, ceramics, nonmetallic minerals, power plant desulfurization, water slag, slag, slag, coal

Pulverizer Wikipedia

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. Vertical spindle roller mill coal types on mill vibration are investigated to identify the potential malfunction of beater wheel mills and their associated components for predictive maintenance purposes.

How Vertical Grinding Mills Work (Coal Pulverizer

· Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mill''s main components, how it works and some

Loesche Grinding Plant for Solid Fuels YouTube

· LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations. Special

Bearing Failures Case Study | Allied Reliability

The asset is a verticallymounted, belt driven grinding mill, as shown in Figure 1. The drive spindle has three (3) bearings: two (2) cylindrical roller bearings and one (1) ball bearing. The mill is being belt driven by a 100 hp, twopole motor. The mill normally operates at 3,150 rpm.

Inerting System Design for Medium Speed Vertical Spindle

Inerting System Design for Medium Speed Vertical Spindle Coal Pulverizers The PRB Coal Users'' Group plans to develop a Design Guide for Mill Inerting as an aid to users when designing a mill inerting system. This is a first draft document by the The Group on the subject of mill inerting. Feedback is encouraged. TABLE OF CONTENTS Preface 2

Cement grinding Vertical roller mills versus ball mills

80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and

LOESCHEMILLS

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM D). 1980 Delivery of first modular coal mill (LM D). 1985 Delivery of first selfinerting coal grinding plant (LM D) for the steel industry (PCI

A Knowledge Based Operator Support/Control

These changes cause a longer coal grinding residence time, higher power consumption, high mill level and recirculating load and high mill dP. The use of very wet coal causes the mill blockage and high bowl pressure. The nonnal mill dP range for CERPlOO3 vertical spindle mills is between 3 kPa in (solid) from which it can be seen

Don''t Forget The Drawbar : Modern Machine

Don''t Forget The Drawbar. Factor in spindle grinding and lost productivity from downtime, he says, and a machine crash resulting from a tool pulling out of the spindle could cost more than 10,000. Many job shops start in a garage with a used mill and a manual lathe.

HLM Vertical Roller Mill

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology. It features in a combination of drying, grinding, classifying and conveying. HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process

ربما ستكون مهتمًا

- أسطواني طحن 1973 الاسمنت

- Primary Crusher Gyratory Crusher Table

- تصميم دائرة إنتاج الأسمنت الدائرة المغلقة

- كسارة صغيرة لبيع كينيا

- Best Grinder For Pax 3

- الحصول على بدء التعدين مينينغتينغينغ كسارة الحجر

- كسارة فكوك كروب مستعمل

- استهلاك محطم كيفية عمل كسارة إجراء التثبيت

- Ball Mill Used For Cement Manufacturing Process

- إيطاليا مصنعين طحن مطحنة

- رائد محطم تصنيعها في الصين

- حجر كسارة تدريب المشغل

- مطحنة لالباريت المستخدمة في

- jaw crusher specifi ion blake type brazil

- Cone Crusher Mantle With Shaft Machining Facilities

- mobile sand crushers for sale

- تأثير تحليل البوكسيت إيران

- غرامة آلات طحن التلك

- سحق آلة جعلت الولايات المتحدة الأمريكية

- مواقع التعدين الذهب للأطفال

- Complete Mica Grinding Mill