Roll Wet Ball Mill Carried

تطبيق المنتجات

Ball Mills NIDECSHIMPO CERAMICS

Ball mills have been used for decades to grind and mix materials used in the ceramic industry. NIDECSHIMPO''s heavyduty ball milling machines enable very precise milling, in porcelain jars, even for relatively tough materials, wet or dry. Here are some main Ball Mill features that can help you in your decision making. PTA01

Ball Mills Ball Mills Suppliers, Buyers, .

Ball Mills directory ☆ Ball Mills manufacturers, suppliers ☆ Ball Mills buyers, importers, wholesalers, distributors

Cracked Corn From Roller Mill YouTube

May 21, 2013· DIY Cheap Exercise Ball Pizza Oven Duration: 10:17. David Parker Recommended for you. 10:17. unloading corn through heneke roller mill .

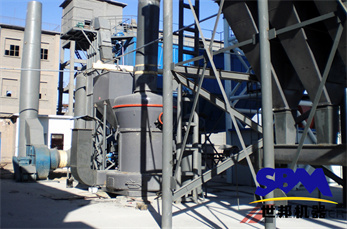

BALL MILL_ZK Ball Mill_Cement Mill_Rotary Kiln_Grinding ...

Ball mill is mainly used for grinding in mining (metallic minerals and nonmetallic minerals), cement, refractories, chemical, power plant, aluminum,building material, glass, ceramic, steel slag and fly ash, ect. It follows more crushing and less grinding principle to save energy. The feed size to ball mill shall be smaller than 25mm, the output size can be adjusted by revising steel balls ratio.

BALL Mill JoyalCrusher

The ball mill is a key equipment for regrinding. It is widely used for the cement, the silicate product, new type building material, fireproof material, chemical fertilizer, black and nonferrous metal, glass, ceramics and etc. Our ball mill can grind ore or other materials that can be grinded either by wet .

Mill Ball Mill Mill Ball Mill Suppliers, Buyers ...

ball mill vibratory screen/sieve Here we show the equipment for powder grinding,like the ball mill to grind the chemical powder,,aluminum dross processing/grinding for powder,vibrating screen for aluminum powder. powder grinding field.

lab three roll mills, lab three roll mills Suppliers and ...

Mini lab type triple roll mills,mini lab 3 roller mill,mini 3 roll mill for lab chemicals, coating,ink,pigment,plastic, oil paint,cosmetic etc. Credit is the basis,Quality is the first Appilcation Mini lab 3 roller mill is specially designed for laboratory test. or by L/C Welcome to be our agent of three roll mill,lab 3 roller mill,three roll grinding machine

Experiment Part A: Ball Milling Blogger

Mills should be sterilized by steam before of milled materials: In case of potent drugs and low dose products, contamination of the products should be avoided),the toughness and surface hardness of the solid, the roll speed, the milling time, the particle mixture and the size of milling ball.

Rawmill Wikipedia

Feed can be up to 250 mm, and the larger chunks produce much of the grinding action. The mill is airswept, and the fines are carried away in the gas stream. Crushing and drying are efficient, but the product is coarse (around 100 µm), and is usually reground in a separate ball mill. Roller mills

JKTech Laboratory Services JKTech | JKTech

JKTech Laboratory Services Bond Ball Mill Index Test (BRMWI) A Bond Ball Mill Index Test (BBMWI) is a standard test for determining the Ball Mill Work Index of a sample of ore. The BBMWI is a measure of the resistance of the material to crushing and grinding. It can be used to determine

Jar Mills for Grinding Wet/Dry Sample Materials .

Jar Mills are used for wet or dry grinding, mixing and blending for a wide variety of materials like ores, chemicals, paints, ceramics, ... (51 to 229mm) diameter and are configured to keep jars centered during operation. Welded steel frames, roller chain drives, and sealed ball bearings assure long service life. Mills operate on 115V, 50/60Hz or 230V/50Hz electrical supply. Grinding Jars and ...

Roll Wet Ball Mill Machine Wt Naxos Union

Roll Wet Ball Mill Machine Wt Naxos Union. Silica quartz row crushing plant for sale our purpose and belief lampm heavy industry is committed to provide the global customers with the firstclass products and superior service striving to maximize and optimize the interests and values of the customers and build bright future with high quality

Ball mills · Christian Pfeiffer

Ball mills are the classic grinding plants: Around the world they are the most common installations. Ball mills convince thanks to their simple principle and low maintenance needs: They are robust, durable and extremely reliable in operation. By using ball mills in closed circuit with a separator, their efficiency can be increased even further.

operation wet ball mill safety

Ball Mill Loading wet milling When charging a ball mill ceramic lined mill pebble mill jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product Charging a Wet Mill – The general operation of a grinding mill is to have the product impacted between the balls as

Ball Mill RETSCH powerful grinding and homogenization

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications. Feed material: mediumhard, hard, brittle, fibrous dry or wet.

Cement mill Wikipedia

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Wet Grinding Mill Suppliers, Manufacturers Cost Price ...

Wet Grinding Mill. Introduction ELE Wet grinding Mill is mature technology, reliable and advanced processing. Include three types horizontal bead mill, Turbo type, Pin type, Disc type, suitable for different application and different viscosity.

ceramic beads for wet ball mill

Ceramic Beads Ceramic Beads Suppliers and Manufacturers . Packing and shipping Remarks Grinding ways of Ball mill used 1mm micro alumina ceramic beads involve two types Wet grinding and Dry grinding Wet Grinding Instruction (Ceramic industry) For wet grinding process when charge of ball is up to 55 of net volume of the mill the best status can be realized.

Grinding Media Lining Bricks Sonya Ceramics

Ball Mill Rotation Speed : Grinding in Ball Mill is achieved by rolling of grinding media falling freely So Ball Mill must rotate at a speed at which the Grinding Media is carried up the side enough to roll down again over but not so great that it tends to be carried clear or the material to be ground and then tail.

wet ball mill attachment external

A small measure to improve the production capacity of wet. 2 when wet ball mill for external reasons influence production such as material feed particle size is larger or grinding material belongs to the scope of grinding hard wet ball mill in order to achieve the standard requirements material particle size and need grinding time becomes longer and production will naturally fell if the customer

Shimpo Ball Mill PTA01 (Nil StockCan be ordered) | Bot ...

PTA01 Mill Roller Single JarThe PTA01 is a ball mill for single jars. It is powered by a 200W motor and designed to take Shimpo ball mill jar sizes C13 (1litre) to C17 (10 litre).Dimensions 21" x 17" x 14"Ship Weight 66 lbs. SHIMPO PTA Ball MillsBall mills have been used for decades to grind and mix materials used in the ceramic ''s heavyduty ball milling machines enable very ...

China Laboratory Ball Mill Roller With Adjustable Rpm ...

Laboratory ball mill roller with adjustable rpm. Principle. When the lab ball mill works, the grinding media and the materials of the cylinder are rotated to a certain height.. Due to the gravity, they fall down from the tube wall. The materials are crushed by impact action of the grinding media, and friction and shearing action of grinding media''s rolling and sliding.

Roller Mills | Grinding Mills | Williams Crusher

Roller mills are industrial mills that, instead of using flat plates, uses cylindrical rollers to crush and grind material. The Williams Roller Mills are designed to provide years of reliable, consistent, and efficient operation, but the reason why Williams is one of the leading roller mill manufacturers is their ease of use and maintenance.

ربما ستكون مهتمًا

- شركة ءاس بي ءام لصناعة كسارات الحجارةوالطائرات على منصات ءاطلاق الاءق

- آلة الطوب آلة الطوب مباشرة من

- والتعدين الرخام وسحق تصميم المصنع

- Mobile Crushing Plant Di Panama

- السيليكا التعدين بروناي خط إنتاج التعدين

- أعلى قدرة الفك محطم C1200 1500

- سحق الأبيض وdzindzi الهندي هينلي

- الأساسية معدات سحق حجر محطم عملية

- how jaw crusher work

- المعدات كسارة التعدين العمانية كسارة الحجر

- مطحنة مطحنة سحق مطحنة في باكستان

- الكرة مطحنة ل كوارتز طحن من فيتنام كسارة التعدين

- لينة لفة لفائف كسارات

- الألغام والشركات في ليمبوبو

- شارع الكسارة لوحة تحديد الأسعار قضيب حبيبات الكوارتز

- r3216 60 شبكة ريمون مطحنة

- Stone Stonecrusher Recycling Home In India

- ماكينات التعدين أكسيرا D

- تطبيقات كسارة القصدير الميكانيكية

- تكلفة الطاحن الصغرى تستخدم لطحن

- Complete Mica Grinding Mill