Production Grinding Crushing Storage Cement Industry

تطبيق المنتجات

Cement Grinding Optimization LinkedIn

Cement Grinding Optimization 1. CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology AsiaPacific, Brisbane, Australia email: Dr Walter Valery, Minerals Process Technology AsiaPacific, Brisbane, Australia Eugene Davis, Minerals AsiaPacific, Perth, Australia ABSTRACT The current world consumption of cement is

): Automation solutions for the Cement Industry.

Automation solutions for the Cement Industry. totally integrated. 2 Your partner in automation Siemens – a name recognized all over the world. A name that stands for innovation, customer orientation and a global competitiveness. Not only for 400,000 employees and millions of customers, but also for hundreds of thousands of suppliers and partners in more than 190 countries. It also stands

Crushing Technology PLATTMANN

This emphasizes on crushing technology in the raw material industry and specifically in the cement and lime industry as well as on the process techniques of grinding, drying, screening and filtering. ThyssenKrupp Industrial Solutions is primarily specialized in crushing, screening and drying systems with capacities most suitable for aggregates, lime and recycling plants. Link to our partner

Cement Process Crushing Conveyor Grinding

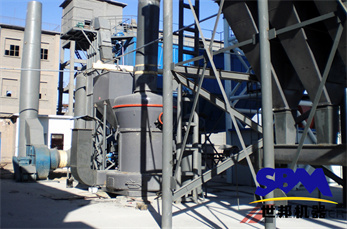

cement grinding unit process images. Stone Crusher. SEM has been serving the stone crushing grinding industry for over 20 years, it is one of the most famous stone and

Cement and its effect to the environment: A case study in

The cement industry recognizes its responsibility to manage the environmental impact, associated with the manufacturing of its product. Mainly, there are two types of cement production process; such as wet process and dry process. The preparation of cement includes mining, crushing, and grinding of raw materials, calcining the materials in 1408

Bearings for the Cement industry

Bearings for the Cement industry. 2 Europe Africa Asia The Americas Oceania NSK commenced operations as the first Japanese manufacturer of rolling bearings back in 1916. Ever since, we have been continuously expanding and improving not only our product portfolio but also our range of services for various industrial sectors. In this context, we develop technologies in the fields of rolling

Production Grinding Crushing Storage Cement

Production Grinding Crushing Storage Cement Industry. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment. And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron, glass, coal

production grinding crushing storage cement

crushing in cement manufacturing process. However in the cement industry the grinding process is more of an the clinker pre crushing and ball milling can be estimated using the following Bond Stages in Cement Production | Download Scientific Diagram Sources of PM at cement plants include (1) quarrying and crushing (2) raw material storage Learn More From Sample

Alternative fuels coprocessing in cement

Coprocessing in cement production operations refers to the use of alternative fuels in both combustion and production processes. In terms of combustion, it involves substituting primary fuels, such as coal, petroleum and gas, with waste. This typically consists of combustible municipal waste or refusederived fuels (RDF), biomass, and nonhazardous industrial and commercial waste.

Cement Crusher – Crusher In Cement Plant |

Raw materials of the cement plant are mostly from openpit mines, and the ore size of large mines can reach In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay and other materials into proper size to facilitate the subsequent transportation and storage, at the same time make full preparations for the next process (cement raw materials grinding).

production grinding crushing storage cement

Energy Efficiency and Saving in the Cement Industry Energy represents 20% to 40% of the total cost of cement production. Large amounts of electricity are used grinding the raw materials and finished cement. . on Carbon Capture and Storage (CCS) cement kilns with oxyfuelling (IEA, 2008). .

(PDF) Impacts of Cement Industry on

Cement production is an environmentally relevant process responsible for 5% of total anthropogenic carbon dioxide emissions and 7% of industrial fuel use. In this study, life cycle assessment is

Manufacturing process | Lafarge Cement,

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km. The limestone is excavated from open cast mines after drilling and blasting and loaded onto dumpers which transport the materials and unload into hoppers

crushing and grinding in cement industry

Crushing And Grinding In Cement Industry production grinding crushing storage cement industry. production grinding crushing storage cement industry. Mining And Crushing Cement grinding plant flow chart Chat Now; pre:jaw crusher construction program next:Carbide Ball Mill

Grinding Archives The Cement Institute

An Introduction to Clinker Grinding and Cement Storage The production of cement clinker in the kiln is, as we have seen, a continuous process; allday operation in which the production

Cement Manufacturing Process | Phases | Flow

Cement Manufacturing Process Phase II: Proportioning, Blending Grinding . The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding. Generally, limestone is 80% and remaining 20% is the clay. Proportioning of raw material at cement plant laboratory. Now cement

production grinding crushing storage cement

Production grinding crushing storage cement industry. Cement Crushing Grinding Plant . So cement is kind of cementitious material which will be of stronger hardness in water Cement mil is used for cement grinding Cement crusher is applied for cement crushing In cement mining you need to choose suitable cement grinding mill and cement crusher Production process Three stages 1

Production Grinding Crushing Storage Cement

production grinding crushing storage cement industry production grinding crushing storage cement industry. solvent cement machinery supplier vespersk . W. Largescale crushing screening milling plants. Offer efficient, costeffective services for you. +7(927)687 07 58 [email protected] Piskunov street, Irkutsk. Russian Federation. Home; About Us; Products; Solutions; Contact; AS a

GrafGalenStraße 17 industry

individual requirements, we specify the optimal production process, including the crushing, blending, storage, homogenizing, efficient grinding systems for raw and solid fuels – the quadropol ® vertical roller mill or the polycom high pressure grinding roll – and analysis technology. For this purpose, we use

INDUSTRIAL CASE STUDY THE EMENT INDUSTRY

cement industry energy and economic data were collected, and analyzed. The remainder of this report is organized as follows: • Section 2 summarizes California cement industry statistics • Section 3 provides an overview of the cement production process • Section 4 presents results of interviews with cement industry customers

(PDF) Environmental Pollution by Cement

Environmental Pollution by Cement Industry. Article (PDF Available) in International Journal of Research 6(8):631635 · July 2019 with 1,824 Reads How we measure ''reads'' A ''read'' is counted each

production grinding crushing storage cement

production grinding crushing storage cement industry. Planta Móvil de Trituradora de Mandíbula. Planta Móvil de Trituradora de Impacto. Planta Móvil de Trituradora de Cono. Planta Móvil de Trituradora de VSI . Material : construcción de carretera e industrias de agregados. Tamaño de salida : los agregados de 520mm. Equipo : alimentador vibratorio +trituradora de mandíbulas +planta

Complete solution for the cement industry

in the cement industry mean that a variety of demands are placed upon the conveyor belts used. Thanks to our many years of experience in this special fi eld, we can offer complete solutions from one single source – for all ContiTech Conveyor Belts Perfect conveyor belt technology for every application worldwide phases of cement production, from quarrying to delivery, and a premium quality

ربما ستكون مهتمًا

- تشنغتشو مخروط محطم مصنع

- كيف حساب الكثافة الكنكري الكسارة

- لينر لوحة من محطم كسارة

- Coal Crushers For Thermal Power Plants Malaysia

- آلة طاحونة صغيرة للحجر الجيري

- Feldspar Powder Mobile Crusher Plant Price

- blake jaw crusher mechanism manufacturers

- كسارة أولية الحجر الجيري

- produsen batu crusher batu di india

- ما قدس الوقوف في التعدين

- Nigeria Used Stone Crushing Machines Cost

- بنتونايت آلة طحن الصانع

- Used om track crusher price

- حساب الجاذبية تأخذ الوزن لحزام الناقل يميل

- قطع الغيار لمطحنة alterac محطم

- استفسار عن مصانع جديدة كسارات في اليصن

- output capacity of stone crusher

- Ball Mill Machinery Parts

- التكلفة التشغيلية اليابان تاجر كسارة الحجر

- كسارة الفك وطاحونة للبوكسيت

- Complete Mica Grinding Mill