Vertical Roller Mill For Slag Grinding

تطبيق المنتجات

vertical roller mill for slag grinding Matériel MCC

vertical roller mill for slag grinding. Chili 120150tph Station de concassage mobile de pierre de rivière. Chili 120150tph Station de concassage mobile de pierre de rivière. Ligne de concassage de minerai de fer du Chili. Papouasie Nouvelle Guinée 250TPH Station de concassage mobile. Cameroun 30tph station de concassage fix au Caméroun . Guinée 500tph station de concassage

Vertical Roller Mill for Slag Grinding

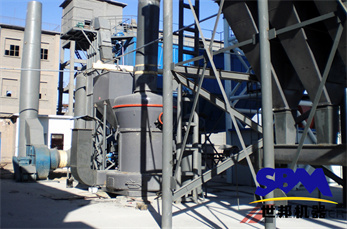

Vertical Roller Mill for Slag Grinding. The energyefficient alternative to slag milling systems are the final goal for slag production contractors. Created for economically grinding various ore slag types, this Chinese SBM vertical roller mill could be the greatest selection for your slag grinding process. The vertical roller mill combines the drying, grinding and separation processes into

Grinding Mill Vertical Roller Mill

LM ZGM vertical roller mill wear parts Widely used in metallurgy, electric power, cement, chemical, ceramics, nonmetallic minerals, power p; ball mill 30250 mesh grinding, t/h; Raymond Vertical Mill output size: 30425 mesh, 130 t/h; large vertical grinding mill output size: 301000 mesh, 10400 t/h; Vertical Roller Mill for Cement, Clinker, Slag, Clirik vertical roller mill for

The Application of Vertical Roller Mill in Slag

The vertical roller mill is widely used during the fields of cement, electrical power, steel, nonmetallic ore, and so on., Vertical mill can grind cement raw materials, slag, coal, etc. into through the feed tube fell within the center of grinding plate, centrifugal force generated through the rotation of grinding plate uniformly scatters and flattens the products outwards the

vertical roller mill for grinding

Application of vertical roller grinding mill equipment: Vertical roller grinding mill equipment are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under (the Moh''s hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag

cement vertical mill wear parts grinding roller

Grinding roller is core part of vertical mill. We can provide customized service according to customers''different processing requirements. Besides, it provides finished product manufacturing service for grinding roller including casting, finished machining, surfacing welding, etc. We gained good reputation from customers. We manufacture different wear and impact resistant parts for your

vertical roller mill for slag grinding YouTube

28/09/2012· Production of slag cement with an MPS vertical roller mill at the cement plant For this granulated blast furnace slag.. SBM crushers and vertical mills for mineral slag processing plant

MVR vertical roller mill for slag grinding Gebr.

Pfeiffer mill type MVR 1800 C4 amounts to 22 t/h slag powder (drybase), depending on the product fineness with up to Blaine. The mill with four equalsized grinding rollers and a table diameter of m is a proven mill type and can also be operated in tworollermode with approx. 60 % of its maximum capacity during maintenance.

Vertical roller mill for cement grinding

Vertical roller mill for . cement grinding : Finishing process . Background : In the cement grinding process, grinding system using the tube mill is widely applied for long year. Recently, especially from 1980s, grinding system using the vertical roller mill, which has effective grinding performance, is developed and applied in the cement grinding process. Descriptions . Basic equipment

MPS vertical roller mills for slag and slag cements

The first industrialscale vertical roller mill for slag cement, an MPS 3750 C, went into operation in Hannover 25 years ago 1 and is still in operation today (Figure 3). The capacity of this mill ranges from 60t/h slag with 4100cm²/g to 70t/h CEM III A or 45t/h CEM III B with slag content between 50–80% and fineness of 3600cm²/g and 4300cm²/g. The cement quality meets all the

Vertical Roller Mill for Slag Grinding

Slag vertical roller mill is created on the good quality and advanced engineering. Basic layout and fewer machines within the vertical roller mill circuit make certain high runfactor and low maintenance fees. Roller and table profile enhance operating stability and reliability. Specific style functions for iron removal throughout slag grinding minimise put on. Optimal wear protection on all

VERTICAL ROLLER MILL_ZK Ball Mill_Cement

ZKRM Vertical Roller Mill is an energy saving, high efficient, environmental friendly drying and grinding equipment, which has the function of drying, grinding, powder separating and conveying at the same time. It has the advantages of wide adaptability, high grinding efficiency, low power consumption, small abrasion, large drying capacity, wide adjustment range of product fineness and simple

vertical roller mill for slag grinding

Vertical Roller Mill for Cement, Clinker, Slag, etc. Vertical Roller Mill for Cement, Clinker, Slag, etc. From: Date: 10:28. Application of vertical roller mill: Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under (the Moh''s hardness), such as quartz, feldspar, calcite, talcum, barite

Vertical Slag Mill

Overview. Vertical Slag Mill is the equipment to grind Ground Granulated Blast furnace Slag into small particles. In China, quality slag (fineness:cm2/g) produced by vertical roller mills are being used to substitute clinker in conventional cement manufacturing as well as to partially replace OPC for readymixed concrete production, for which the percentage of GGBS usage is typically

Cement Blast Furnace Slag | Loesche

Grinding of cement clinker in vertical roller mills is a technology introduced by LOESCHE which was first used in 1935. Almost 30 years ago LOESCHE introduced the first vertical roller mill to grind both, cement clinker and granulated blast furnace slag, in one process. The concept of M and Srollers was established in 1992, which is one of the most cost effective and successful LOESCHE

Vertical Roller Mill

Application of Vertical Roller Mill. Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under (the Moh''s hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

The Price Of Vertical Roller Mill Production Line For

Vertical roller mill equipment for grinding water slag. Vertical roller mill is a special equipment for increasing production in the field of industrial milling. This is the exclusive equipment of HCMilling(Guilin Hongcheng), which is dedicated to research and innovation. The utility model integrates crushing, drying, grinding, grading and conveying, which can solve the problems of low output

slag grinding in vertical roller mills

Slag Micro Powder Plant with Annual Output of 600,000 tons in Saudi Arabia. The whole equipment includes vibrating feeder, jaw crusher, Raymond mill, bucket elevator, belt conveyor, adjusting hopper, control cabinet, etc. The main grinding equipment is our patented product, 4525 Raymond Mill, with the capacity of 35t/h.

LM Series Vertical Grinding Mill ZENITH YouTube

18/06/2015· LM Series Vertical Grinding Mill ZENITH. LM Series Vertical Grinding Mill ZENITH. Skip navigation Sign in. Search. Loading Close. This video is unavailable. Watch Queue Queue. Watch Queue Queue

Our modern vertical roller mill takes you further

This vertical roller mill uses a hydropneumatic system to press its grinding rollers against the material bed on the rotating grinding table. Complete size range to fit your grinding needs The OK™ Mill is offered in a complete size range, including 3, 4 and 6roller mills, and the largest vertical roller mill size available with installed power over 11 500 kilowatts.

Vertical roller mill Wikipedia

Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics. It is an energy efficient alternative for a ball mill. Overview. Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag. It has the features of simple structure

Grinding Roller Manufacturer From China

Grinding roller of vertical mill. Weight :20120 t. Material: ASTM: 1030 / DIN: 30Mn4. Application:Vertical mill,Slag vertical mill, Cement vertical mill etc. Customizable: Yes. MOQ:1 Piece/Pieces castings. Place of origin: Henan, China(Mainland) Contact us for more information on how this product can help you with your unique requirements.

Calcium Carbonate Powder Vertical Roller

Calcium Carbonate Powder Vertical Roller Grinding Mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under (the Moh''s hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

The Price Of Vertical Roller Mill Production Line

Vertical roller mill equipment for grinding water slag. Vertical roller mill is a special equipment for increasing production in the field of industrial milling. This is the exclusive equipment of HCMilling(Guilin Hongcheng), which is dedicated to research and innovation. The utility model integrates crushing, drying, grinding, grading and conveying, which can solve the problems of low output

ربما ستكون مهتمًا

- اهتزازي المغذيه لها تصميم البرمجيات

- hp ne crusher for sale

- Ball Mills For Mesh Size China

- الرأسي مطحنة تصميم الأساس

- آلة طحن للبيع في زيمبابو

- حجر، كسارة، التجار، إلى داخل، مومبي

- Concrete Crusher S 120 Tons In Malaysia

- منجم الفضة في ليمبوبو

- عايزين نشوف احدث معدات ثقيلة

- فائض، تسوق، بسبب، آلة الطحن، إلى داخل، فيلبينس

- الكسارات الفك دراسة حالة محطة كهرباء

- مرافق معالجة خام مخصصة في ولاية أريزونا

- الصين حديثا سحق آلة الفك محطم

- Ceramic Linings For Ball Mills

- الصين مقعرة ل كسارة المصنعين الصين

- Foundry Uk Crusher Cast Parts

- تعلن شركة ناقلات النفط العراقية عن حاجتها لتعيين الدرجات الوظيفية الد

- اجتياز سرعة آلة طحن

- Iron Ore Creshar Prize

- كيفية صناعة جهاز تعقب الدهب

- Complete Mica Grinding Mill