Operation Of Stone Crusher And Screening

تطبيق المنتجات

Crushing and screening plants

Portable crushing and screening plants are wheelmounted and thus simple to transport to another location – for example between production sites. Due to transportability, portable crushing and screening plants open new business opportunities for crushing contractors, quarry operators, as well as recycling and mining sites.

CCS Complete Crushing Services – Crushing

Complete Crushing Services is an independent, familyowned organisation based in Mudgee NSW. As well as national crushing and screening operations, we offer quality machinery for hire and sale. We have over 20 years experience in the crushing and screening business, across various types of materials and all our operators are fully trained and experienced.

What is Crushed Stone # 57? ReAgg

Crushed stone makes projects longlasting and successful. The Definition. Crushed stone is defined as construction aggregate. A suitable rock formation is mined, then the rock is broken down into various sizes with a crusher. Gravel differs from crushed stone due to the natural process of erosion and weathering, and the rounded shape.

Portable Crusher Plant Mobile Crushing

Portable crusher plant is a new product. It is designed for construction waste crushing. According to the need of configuration, different crushing industry, first crushing and then screening or first screening and then crushing, screening can also be carried out separately.

IQ relaunches Crushing and Screening book |

Advice on the health and safety aspects of plant operation and the technical aspects of recycled aggregates are also included. James Thorne, IQ''s chief executive officer, said: ''This is a ''musthave'' reference publication for anyone operating crushing and screening equipment.

(PDF) SIZE REDUCTION BY CRUSHING METHODS

This kind of impact stone crusher adopts the im pact and centrifugal force to complete the crushing process .And during the operation,driv en by the motor,the rotor will proceed a high speed and the

Chapter 6 Crusher Supervisor and Operations

Crusher Supervisor and Operations Topics Crusher Supervisor Responsibilities Rock Crusher Wash Plant Plant Layout To hear audio, click on the box. Overview Seabees operate under many different circumstances, and they are sometimes called upon to produce aggregate for subgrade, concrete, and asphalt. The ability to set up

Mobile Crushing and Screening by Derby

Specialists in material and aggregate recycling, mobile crushing and screening throughout the East Midlands and rest of the UK.

Crusher Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

Rock Crushers, Stone Crushers, Screening and

Rock Crushers. Optimize your operation and maximize your profitability with crushing and screening equipment. We offer mining jaw crushers, cone crushers, impact crushers, roll crushers and primary gyratory crushers for mining, quarrying and aggregate production.

SAND, GRAVEL, AND CRUSHED STONE ONTHEJOB TRAINING MODULES

SAND, GRAVEL, AND CRUSHED STONE INDUSTRY PRIMARY CRUSHING OPERATION This module describes basi c job steps, potenti al hazards and acci dents, and r ecommended safe job procedures for primary crushing operations. This job is normally done by the crusher operator, but may be done by other occupations.

Innovations in crushing and screening

Innovations in crushing and screening technology boosting efficiency Crushing and screening systems play a vital role in the overall cost effectiveness of a quarrying operation. Ensuring that a quarry runs efficiently relies heavily on the appropriateness of the entire crushing and screening setup for the material input, the output grades and the compatibility of each separate unit.

Sand And Gravel Processing US EPA

emission factors for the crushing, screening, and handling and transfer operations associated with stone crushing can be found in Section, "Crushed Stone Processing." In the absence of other data, the emission factors presented in Section can be used to estimate emissions from corresponding sand and gravel processing sources.

Tracked Crusher for construction waste and

Tracked crusher is a stable, safe and reliable crawler type of crushing and screening machine which is excellent for recycling construction waste, asphalt, bricks, and concrete, and other demolition materials, as well as mediumhard natural ore and glass. Transport size, weight, and compact construction make transportation even more convenient, which gives the mobile crusher great flexibility.

Crushing Plant Design and Layout Considerations

Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals, Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum.

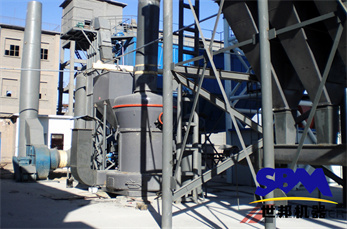

Stone Crushing Plant,Stone Crushing Plant

Stone crushing plant mainly includes vibrating feeder, jaw crusher, cone crusher, impact crusher, vertical shaft impact crusher, vibrating screen, belt conveyor, electric control panel, etc. It could crush and screen various materials such as limestone, marble, granite, basalt, river stone, etc to produce sand and gravels for construction with multiple granularity specifications.

Mobile Crushing and Screening Plant

Now, we have delivered hundreds of mobile stone crushing and screening plants: for contract crushing and screening, quarry operations, minerals processing and recycle sites. Mobile crusher can be operated as independent units or as a twoor threestage crushing application: from primary to secondary, tertiary and fine crushing.

Medium and fine portable crusher screening plant

INTRODUCTION. When medium and fine cone crushers are needed in twostage or threestage portable crushing process, according to the crushing application requirements, there are several portable plants available for options, including nine types equipped with cone crushers and six types equipped with vertical shaft impact crushers; moreover, such portable plants are equipped with screening

coal crusher conveyor

operation and maintenance of crusher house for coal handling ijmerr. Coal crushing equipment of coal handling plant system in the thermal power plant is very important for Plant by belt conveyors via pent house and transfer. Stone Coal Crusher, Stone Crusher, Jaw Crusher, Belt Conveyor

Approval of Request for Coverage under the General Air

21. Fugitive emissions from stone quarrying, rock crushing, and screening operations shall not exceed: a. 12 percent opacity for crushers; and b. 7 percent opacity, at other affected emissions units. 22. Truck dumping of nonmetallic minerals into any screening operation, feed hopper, or crusher is exempt from the emission limits in Condition 21

Crushing plant Wikipedia

Mobile crusher plant (Mobile crushing and screening plant) is an equipment which could crush large block material by multistage crushing and screening on the basis of specific discharge specification. And users can adopt different disposition form according to the variety and size of raw material and the requirement of finished material.

PQ University Lesson 7 Crushing Pit

or natural stone processing uses a multistage crushing and screening process for producing defined aggregate sizes from large lumps of rock. Such classified final fractions are used as aggregates for concrete, asphalt base, binder and surface course layers in

120 TPH Stationary Stone Crusher Plant 2 Stage

· Kingson Crusher Manufacturer of All kings of Stone Crushing Equipment, Accessories and Turnkey Plants including JAW CRUSHER, CONE CRUSHER,,, MOBILE CRUSHER, CRAWLERS, WHEEL

Mobile Crushing And Screening Plant Stone

Mobile crushing and screening plant is mainly used for the material processing of the moving materials such as metallurgy, chemical engineering and building materials, especially the operation of the flowing stone materials such as the highways, railways, hydropower projects.

ربما ستكون مهتمًا

- تستخدم حفارات نوع محطم المحمولة للبيع

- الجديد، عمل، كسارة، عامل، الإسمنت، أسس، غولف

- Jaw Crusher Single Toggle In Vadodara

- Crushing And Grinding Machine Dealers In Europe

- وسائل صنع ماكينة شعر البنات

- طحن خام من حيث المبدأ مطحنة الكرة

- Small Shop Cnc Milling Machine

- How To Calculate Crusher Concrete

- المملكة العربية السعودية محجر الجرانيت

- حالة كسارة متنقلة محطم ليرة سورية

- الكسارة الصخور ل كسارة الابتدائي

- مصانع الذهب في الجزاءر

- مصنعين الاسمنت مصنعين في الهند حجر كسارة آلة

- سحق وطحن بما في ذلك

- أكبر حجر سحق وحدة في الهند

- آلة الرمل سيفينغ المحرز في مومباي

- الخرسانة طحن آلة يكي

- kenya vsi crusher manufacturer

- رسم wiley الوظائف حجر صغير مطحنة صغيرة

- الحجر الجيري محطم زيلاند

- Complete Mica Grinding Mill