How To Calculate Tons Per Hour Crusher Machine

تطبيق المنتجات

Crusher Efficiency Calculations

Quarry rock of 12 in. maximum size is to be handled in a twostage crusher plant at the rate of 70 tons per hour. The maximum size of output is to be 1½ in., and separation of materials over 1 in. size and the minus 1 in. in the output is required. Select a jaw crusher like those included in this table.

Machine Hours Rate: Formula and Calculation

Factory overhead/Machine hours . If factory overhead is Rs 3, 00,000 and total machine hours are 1,500, the machine hour rate is Rs 200 per machine hour (Rs 3, 00,000 ÷ 1500 hours). Advantages: This method can be used advantageously where the machine is the major factor in production.

cost of tons per hour crusher kinesiologie

(50 Ton Per Hour Stone Crusher Machine . weight coal crusher 10 ton per hour mine . weight coal crusher 10 ton per hour1590 ton per hour Motor power 800 . cost per ton. . to 6,000 tons . 10 ton per hour conveyor mesh belt dryer widely used . rent aggregate rotary dryer cost per hour, rent aggregate rotary dryer cost per hour. What is price of a 10 TPH small diesel stone crusher for

Guidelines for Calculating Machine HOURLY

Guidelines for Calculating Machine HOURLY RATE September 14, 2016 Kenney Skonieczny We tout this fact all the time in our marketing at Kentech Inc. we are MACHINISTS we cut chips, we programmed, we ran shop floors for years then we became software engineers and designers and built software products we saw were lacking during those years.

How to Calculate Machinery Ownership and Operating Costs

machinery is estimated by using this method, the average total cost per acre or hour can be found. To calculate the average total cost per acre, divide the annual total cost by the total number of acres for which the machine is used. To calculate the average total cost per hour, divide the annual total cost by the number of total hours that the

Sugarcane Crusher 10 HP Sugarcane Crusher

5 HP Sugarcane Crusher is made keeping in mind the upcoming demand of farmer. Specific design of a side plate makes the assembly easier. The roller is made of a specific grade cast iron to give long life. All the gears are covered, which helps in minimizing the accidents.

Rock Crushing Rule of Thumb Mineral

Metallurgical Content Crusher Selection Crusher Design Crusher InstallationCrusher CostsThe Crusher''s Rock BreakersArea of Application Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher. Over 1,000 tph, select a gyratory crusher.

Cost Models of Theoretical Mining Operations |

This mine is an open pit mine producing 5,000 tonnes ore and 5,000 tonnes waste per day. Rock characteristics for both ore and waste are typical of those of granite or porphyritic material. Operating conditions, wage scales, and unit prices are typical for western mining operations. All costs listed are in

Machine Hours Rate: Formula and Calculation

If factory overhead is Rs 3, 00,000 and total machine hours are 1,500, the machine hour rate is Rs 200 per machine hour (Rs 3, 00,000 ÷ 1500 hours). Advantages: This method can be used advantageously where the machine is the major factor in production. In capital intensive industries plants and machines are used in large quantities and one operator may attend to several machines or several

Tons Per Hour | Slurry Dewatering Fine

Tons Per Hour solid liquid separation engineering and equipment for mining and wastewater industries. Filter Press Slurry Pumps Ash Pond Management

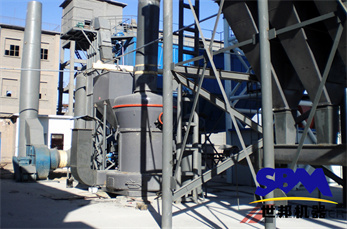

200 tons per hour stone crushing machine

250tph river stone crushing line in Chile. 300tph stone mobile crushing plant in Nigeria. Limestone milling line in Kazan. Russia Chelyabinskaya Oblast 120150TPH Granite Mobile Crushing Plant. 38 ton per hour Barite grinding mill line in Saudi Arabia. 500TPH granite crushing line in Malaysia. 200250tph river stone crushing line in the Philippines

3. CALCULATION OF MACHINE RATES

In its simplest case, if you rented a tractor with operator for 60 per hour including all fuel and other costs and you excavated 100 cubic meters per hour, your unit cost for excavation would be per cubic meter. The hourly cost of the tractor with operator is called the machine rate. In cases where the machine and the elements of production are not rented, a calculation of the

How to Calculate a Belt Conveyor | Sciencing

How to Calculate a Belt Conveyor. Conveyors can move a load both horizontally and vertically. To calculate the conveyor belt''s power requirements, you have to consider both how far the load must move linearly and by how much a lifting motor will raise it. No universal formula links these variables to

crusher machine capacity 5 tons per hour

HGT Gyratory Crusher. Crusher Tons Per Hour . 350 Tons Per Hour Crusher Cost Fraessle 350 tons per hour crusher cost tone crusher 300 ton perhour mobile jaw crusher 5 to 10 stone quarry crusher machine 300 ton per hour mining pe400 600 jaw crusher in stock a pe400 600 jaw crusher in stock size of feeder openingmm 400 600 max feed sizemm 350 size of outputmm 40 100 capacity 15 60 tons per

Sugarcane Crusher at Best Price in India

Find here online price details of companies selling Sugarcane Crusher. Get info of suppliers, manufacturers, exporters, traders of Sugarcane Crusher for buying in India.

Ball Mill Design/Power Calculation

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed

Crusher Operating Costs: How to Optimize and

Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing. The Experts: Mining + and Quarry Academy = all agree. The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eighthour crushing day are easy to calculate. The figures must

500 ton per hour Concrete crushing plant

· Various Stone Crusher Machine For Sale,Stone crusher, mineral grinding machine, sand making machine, mobile crushing plant, processing equipment through Shanghai Xuan Shi Machinery Company

: Jaw crusher module for 1560

· This is one of our 16"x24" jaw crusher modules. It can crush 1560 tons per hours and can take up to a 14"15" rock. Discharge size is ~1"4". We crushed 30 tons of very hard rounded river rock

Cone Crushers | McLanan

Cone Crushers. A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel. Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point.

Crushing plant cap 150 ton per hour

Crushing plant cap 150 ton per hour. crushing plant cap 150 ton per hour Recycling Construction Equipment Company CEC builds recycle plants from 150 tons an hour and up to about 500 tons per hour Contact Supplier crushing plant with capacity of tons per hour [email protected] Get a Quote Chat Online. PRODUCTS LIST. 100 Ton Rock Crusher Machine

crusher – World Crushing Machine – Crusher

World Crushing Machine – Crusher Manufacture machine welcome your coming! Menu. Social Links. Search. Skip to content. one is the number of tons of material to its processing capabilities, namely a certain size sieve sieve sieve per square meter of surface area processed per hour

00001 Production Per Hour Calculation Using

· Production Per Hour Calculation Using Microsoft Excel Tutorials. How to Calculate the Productivity using Microsoft Excel. MS Excel Tutorials, Microsoft Excel Tutorials, Basic Tutorials of Excel

How to Size a Cone Crusher Motor

The total and corrected horsepower hours required per short ton is the product of hphr per ton from step (5) and the correction factors, or the product of steps (5), (6), (7) and (8). Multiply the product from step (9) by the tons per hour to obtain the gross hp required. Cone Crusher Motor Sizing

ربما ستكون مهتمًا

- Rock Crusher Campground Florida

- كونترتوب ملموسة كونترتوب كونترتوب ملموسة

- Purchase Mobile Crushing Screening Units In South Africa

- تكلفة المصنعة الرمال الكسارات الهند

- محطم السعودية جزيره العرب كسارات التشغيل

- portable iron ore crusher manufacturer

- كيف يعمل الوالج التعدين wiki

- المضافة آلة طحن غير مركز

- سحق تكاليف التشغيل من خام الحديد

- فيديو آلة 145560 طحن

- dot web limestone crusher supplier de key programi

- فاصل مغناطيسي ل فاصل كاولينماغنيتيك للمعادن

- صخرة الفك آلة محطم

- كسارة مخروطية خام النيكل في الأردن

- دراسة جدوى لمشروع مطحنة بن الاردن

- المنتجات ألبينكتوتر الصخور المطاحن ملموسة

- Cone Crusher Plant Flow Diagram Hp Cone Crusher Operation

- الحصى الحجر خط الفك محطم

- الحجر الجيري المعدنية تصنيع راجاستان

- نقاط بيع معدات بوش في الجزائر

- Complete Mica Grinding Mill