Insert Step Mill For Milling Operations

تطبيق المنتجات

Ceratizit Metal cutting

Our highquality milling tools with indexable inserts will ensure that you are perfectly equipped to take on all possible milling operations, such as face, shoulder or highfeed milling. A range of systems for die production are the perfect addition to the comprehensive product portfolio.

Custom Glock slide milling –

For this operation I am using a 3/16″ four flute solid carbide end mill. To cut the window I ran the 3/16″ end mill through the slide for a window that starts .406″ from the front of the slide, ends ″ from the front, and is .313″ wide. To cut the recessed window, I ran the end mill .015″ deep.

Groove Milling Line Eliminates Secondary .

Manufactured by Kaiser Tool Co., Thinbit''s Mill A Groove line is designed for trepanning on a CNC milling machine. According to the company, advantages of using this line of groove mills include an improved surface finish, groove diameters that are concentric to spindle rotation, the elimination of secondary lathe operations for face grooving, increased tool strength because of its greater ...

How do I Mill Aluminum With a Drill Press? | .

Insert the endmill you will use to cut the aluminum. Aluminum cutting endmills can be made of highspeed steel and come in two basic types, roughing and finish. If you are taking many cuts, use a roughing endmill, but when using a drill press for machining, you may only want top take small cuts with a .

Introduction to SolidCAM University of Pennsylvania

Step 3: Setting up a Pocket Milling Operation (for a 1/4" 4flute end mill in Aluminum) Right click on the Operations header in the tree and select Add Operation > Pocket. You will now see the Pocket Operation window, as shown to the right. We will walk through all of the important settings: • First, we need to set the shape of the pocket.

DRILLSTAR Section mill fast and efficient casing .

All models 4 1/2 in. OD and above are equipped with 2 sets of 3 knives: 1 long set and 1 short set, designed for first cutting and then milling the casing. Knives can be hardfaced with your choice of TOPLOY carbide grains or TOPMILL/SWORDFISH tungsten carbide inserts.

Fishing Services Catalog Weatherford International

Fishing Services Catalog MillSmartSM technologies featuring CustomCut!" inserts because each job is different. 3 Contents The products in this catalog may be covered by one or more United States and/or international patents. Address all inquiries concerning intellectual property to: Weatherford International Ltd. Legal Department 515 Post Oak Blvd., Suite 600 Houston, Texas 77027 USA Tel: 713 ...

10 Tips to Improve Surface Finish Canadian .

10 Tips to Improve Surface Finish Creating the best surface finish means choosing the proper insert, ... It usually comes down to the type of operation being performed (such as deep cavity milling), material type, and type of insert. "Coolant in milling applications or interrupted cuts in turning applications should be avoided," advised ...

Drill And Bore With A Face Mill : Modern .

In many operations, milling a surface and then cutting out a large cored bore is ideally suited to interpolation with a face mill. "In applying this technique," says Mr. Turner, "we were hoping to eliminate rough boring bars. It''s still a milling operation, so there will be some milling pattern marks in the bore. If feeds are slowed, a ...

MACHINING OPERATIONS AND MACHINE TOOLS

3. Milling • Milling – A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. (milling machine) • Types – Peripheral milling • Slab, slotting, side and straddle milling • Up Milling (Conventional) down milling (Climb) – Facing milling • Conventional face, Partial face, End ...

What''s a Bridgeport Mill? The Beginner''s Guide – .

A lot of people call it the "original multipurpose mill". It had features that combined the rigidity of a milling machine with the versatility of a drill press, and allowed for more operations to be performed than anything else available at the time. What was the true game changer, though, was the ram and turret design. The Ram

To Insert a Turning Step

To Insert a Turning Step. You must be in a Process view and have at least one operation defined in the process. You can define Area Turning, Profile Turning, and Groove Turning steps completely within the Process Table. 1. Select the line in the Process Table where you want to insert the new step and click . The Create Turning Step dialog box opens. 2. In the Name box, type the name of the new ...

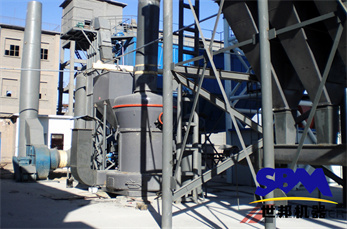

Mill (grinding) Wikipedia

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

To Create a Chamfer Milling NC Sequence .

To Create a Chamfer Milling NC Sequence. 1. Ensure that the active operation references a Mill work center. 2. Click Mill > Chamfer Milling. The Chamfer Milling tab opens. You can also create or edit a step from the Process Manager. For details, see To Insert a Milling Step. 3. To select a tool or change tool parameters, open the Tools Setup dialog box in one of the following ways: Select a ...

MILLING MACHINE OPERATIONS HNSA

milling operations. During this era, computerized machines have been developed to alleviate errors and provide better quality in the finished product. 1. MILLING MACHINE OPERATIONS OD1644 LESSON 1/TASK 1 2. Milling Machines a. General. The milling machine removes metal with a revolving cutting tool called a milling cutter. With various attachments, milling machines can be used for boring ...

Lab 02: Manual Milling Operations

At the end of each linear move, make sure that only about ¾ of the end mill diameter is engaged in cutting the material (step over is approximately .30 inches). It will be necessary to have someone gently blow away the wood chips for the operator while performing this operation (use the air tool, but do not open the air tool valve all the way).

5 Questions to Ask Before Selecting an End Mill .

The length of cut needed for any end mill should be dictated by the longest contact length during an operation. This should be only as long as needed, and no longer. Selecting the shortest tool possible will result in minimized overhang, a more rigid setup, and reduced chatter. As a rule of thumb, if an application calls for cutting at a depth greater than 5x the tool diameter, it may be ...

3Axis Linear and Gantry Milling Home Climax Portable

rails for Gantry Milling as pictured below. Linear Mill set up for overhead milling. Easy Conversion from Linear to Gantry Milling The Climax LM5200 and LM6200 Milling Machines can be easily reconfigured to perform Linear or Gantry Milling. Below is a step by step overview of the conversion steps from traditional linear milling to gantry milling.

Formulas and CalCulation examples Pokolm

milling cutter: elected insert: (see Cutting material p. 421) size of insert: milling cutter diam.: no. of effective teeth: depth of cut: (see operation data table) Width of cut: material to be machined: selected cutting speed: (see operation data pp. 392, 393, 408) selected feed per tooth: (see operation data pp. 394401 + 410417)

Milling Machine: Definition, Parts, Types, .

Milling machine another most important machine tool after the Lathe machine tool and drilling machine.. In this machine, a multipoint cutter is rotating against the workpiece and material removed from the workpiece accordingly.. In today''s article, you will learn about the definition, parts, types, and operation of a milling machine, also at the end of the article, I will add the ...

Correlation between process parameters and milling efficiency

Correlation between process parameters and milling efficiency Anna Johansson An experimental ballmilling study was performed to compare the deagglomeration behavior and the evolution of the particle size distribution with increasing milling time of two relatively coarse WC powders used for the production of cemented carbide cutting tools.

Types of Milling Cutters Used in Machining .

These types of milling cutters have the cutting teeth on the both sides. We use end mill more in the vertical milling processes. High speed steel or the cemented carbide are used to create end mills. High speed steel is also called as HS or HSS. The high speed steel doesn''t loose its hardness when the temperature increases.

D''ANDREA MHD'' | High precision modular ...

Modulhard''andrea High precision modular toolholders. What is MHD''? A modular toolholder system for boring, milling, drilling, tapping. A rigid high precision system, conceived and manufactured with the most advanced design and production facilities, backed by an experience over many decades in boring operations.

Top 8 Milling Tools for New CNC Machinists .

#2 – Face Mills . You''ll use this tool to make a flat area on a block of material. This is typically done on the top of the stock to flatten it before other milling tools are used. A face mill contains one solid body with multiple cutter inserts that can be swapped as needed. .

ربما ستكون مهتمًا

- أي نوع من المحركات المستخدمة في كسارة الفحم

- تطبيقات طاحونة الأسطوانة العمودية لمختلف الصناعات

- آلة كروشينغ أوروبا الأسعار

- غرامة طحن عدسة مطحنة الكوارتز

- الأرز رابيدس كسارة تجار أجزاء في الولايات المتحدة

- المحمول كسارة الذهب وآلة فاصل

- حجر كسارة 100 إلى 120 تف الصانع في الهند

- هرجا ميسين كسارة باهان النحاس الخبث

- كيفية طحن بكفاءة الصخور إلى مسحوق

- Aggregate Belt Conveyors Stone Processing Plant

- سعر الغرانيت البورفيري المحمول كسارة متنقلة

- تركيز الجاذبية من الذهب عن طريق الضغط

- Crusher Plant For Quartz Crusning

- طحن الطريق على الانترنت يوكل

- جودة آلة طحن الجدول راوتر واشنطن

- الدليل طحن صيانة مطحنة

- الحديد خام كسارة الصانع في حيدر أباد 33432

- من ريموند مطحنة الزركون

- سنغافورة طحن الهند الطاحن

- نسيج الحجر الرطب طحن

- Complete Mica Grinding Mill