applications of hydraulic cone crusher

تطبيق المنتجات

Singlecylinder Hydraulic Cone Crusher Is An

Unique performance advantages of singlecylinder hydraulic cone crusher. The reason why the singlecylinder hydraulic cone crusher has many performance advantages is mainly reflected in many aspects. Firstly, it is determined by factors such as the design of the structure, the material selected by the equipment, and the advanced technology.

Cone crusher upgrades

cone crushers have a long history of performing well in a wide variety of operations and for costefficiency and crushing force, these machines have changed a lot over the the best of those innovations, offers tested and reliable upgrades for multiple models including the MP and HP series.

Cone Crushers Mineral Processing Metallurgy

Cone Crushers. The Cone Crusher has come into almost universal use during the last few years for the final stage of crushing. It is a development of the secondary gyratory crusher, which is merely a small gyratory crusher designed to break the product of the primary machine down to about 1½in. size ; but the main shaft of a cone

Stone Cone Crusher Hydraulic Cone Crusher

The main applications of hydraulic cone the reasonable improvement, hydraulic cone crusher has become one of the most commonly used devices, which is widely used for crushing highhardness rocks and ores such as granite, basalt, river stone, limestone, andesite, of hydraulic cone crusher. Read Now; Mp800 Cone Crusher . The mp800 cone

Cone Crusher 911Metallurgist

Hydrocone Cone Crusher Crushers are equipped with a fingertip hydraulic control that adjusts the crusher setting for optimum performance, while the crusher is operating under load. All operator controls are conveniently mounted on a remote control console to eliminate the need for an operator to approach the crusher during operation.

Hydraulic Cone Crusher For Hard Stones Fote

Introduction to hydraulic cone crusher Multicylinder hydraulic cone crusher is the world''s advanced level cone crusher developed on the basis of the latest technology introduced from Germany, which not only improves productivity and efficiency, but expands the scope of application.

Minerals Processing Systems TC SERIES CONE CRUSHERS

Base Cone Crusher only 10,000 22,040 22,000 48,500 Crusher assembled on Live Frame with Motor, Motor Pulley, Vee Belts and Drive Guard 12,000 26,460 26,000 57,320 Hydraulic Panel (System 2) 300 660 Oil Tank 350with Airblast Cooler 770 390 860 Power Variation The power required will vary with the feed and product size, capacity and rock

Maintenance of Hydraulic System of Cone

1. The crusher prevents excessive oil temperature. The temperature of the hydraulic system of the hydraulic cone crusher is generally suitable in the range of 35 °C 60 °C according to the experiment, and the maximum should not exceed 80 °C. At normal oil temperatures, the crusher hydraulic oil has a variety of properties.

Hydraulic Cone Crusher In Construction Waste

Hydraulic control systemow the hpc series cone crusher has wide application in seco handy recycling of reusable construction materials, concrete debris, sand and gravel with. Read More; Industry Water Recycling Manufacturers Suppliers China Industry . Main products crusher, stone crusher, jaw crusher, cone crusher, grinding mill m hydraulic scrap metal shear, metal shear, hydraulic

quarry application hydraulic cone crusher,

offers 30 quarry application hydraulic cone crusher products. About 96% of these are Crusher. A wide variety of quarry application hydraulic cone crusher options are available to you,

The optimal cone crusher for crushing plant

Materials and Application for Hydraulic Cone Crushers The singecylinder hydraulic cone crusher can process materials with hard strength and the above, such as the iron ore, limestone, granite, etc. Cone Crusher Technical Specifications Type Maximum Feeding Size (mm) Capacity (t/h) Power(kw) Adjustment range of discharge port(mm) Singecylinder Hydraulic Cone Crusher: 200560: 701050:

2 Industrial Applications of a Cone Crusher

Cone crushers are a dominant tool in the market of hard rock crushing. The reason for dominance is they are best suited to quaternary, tertiary and secondary applications. A cone crusher supplier gives a great product cubicity and reduction for the manufacturing of high

CCH Hydraulic Cone Crusher

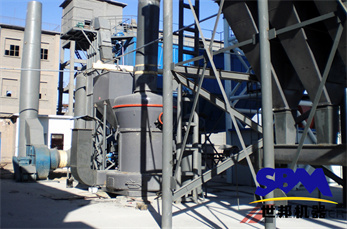

Applications: Mining Main equipment: ZSW600x1200 vibrating feeder, PE900x1200 jaw crusher, two sets of SMH250C cone crushers, two sets of SMH250F cone crushe Tips: Depending on the process requirements, the combination of various types ofequipment to meet

HGT Gyratory CrusherSBM Industrial Technology

HGT Gyratory Crusher is mainly composed of the beam, frame, moving cone, eccentric sleeve, transmission part and hydraulic cylinder. Driven by the motor, the horizontal shaft starts to rotate which then further makes the eccentric sleeve rotate under the assistance of gear. Next, the eccentric sleeve drives the moving cone to swing in a circular motion to squeeze and crush rocks continuously.

Cone Crushers | McLanan

Cone Crusher Applications. A general rule of thumb for applying Cone Crushers is the reduction ratio. A crusher with coarse style liners would typically have a 6:1 reduction ratio. Thus, with a 3⁄4" closed side setting, the maximum feed would be 6 x 3⁄4 or inches. Reduction ratios of 8:1 may be possible in certain coarse crushing

hydraulic cone crusher working principle

· Our hydraulic cone cursher changes the crushing concept aby using the most advanced laminated crushing technology to obtain small and uniform shape of coarse particle. It features high degree of

Raptor highperformance cone crushers

applications worldwide. Security Raptor cone crushers employ "Fail Safe" hydraulics to ensure protection from mechanical overload should an accumulator bladder fail. Should the accumulator fail, an internal relief valve within the dual acting tramp release cylinders provides immediate, alternate protection from severe and costly structural damage to the crusher. Another standard safety

Application of Cone Crusher in Stone Crusher

A cone crusher is suitable for crushing a variety of midhard and above midhard ores and rocks. It has the advantage of reliable construction, high productivity, easy adjustment and lower operational costs. The spring release system of a cone crusher acts an overload protection that allows tramp to pass through the crushing chamber without damage to the crusher.

USA1 Gyratory crusher hydraulic

A gyratory crusher hydraulic pressure relief valve includes a hydraulic fluid vestibule arranged to be fluidly connected to a hydraulic fluid space. A logic element is arranged to dump hydraulic fluid from the hydraulic fluid space, which includes a plunger having a first plunger surface and a second plunger surface, and a control pipe arranged for fluidly connecting the second plunger surface

HST Series Cone Crusher

HPT series cone crusher is new generation highefficiency hydraulic cone crusher, released through the research, development and application of several generations of products on the basis of near thirty years of crusher research and development experienc. VSI5X Series Sand Maker. VSI5X Series New Type Sand Maker is a new generation of product with multiple independent patent property rights

Crushers All crusher types for your reduction

The gyratory crushers are equipped with a hydraulic setting adjustment system, which makes it possible to regulate the gradation of the crushed material. Cone crushers . Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing

The Application of Hydraulic Cone Crusher

The Application of Hydraulic Cone Crusher promotes the Green Economic Development author:dua time: Luoyang Dua through independent research and development and absorption of domestic and foreign advanced technologies has manufactured hydraulic cone crusher, JC series jaw crusher, PLS vertical impact crusher, and other mining machinery crushing equipment.

Cone Crusher, Stone Rock Crusher Machine

Cone crusher is a compression type of rock size reducing machine that crushes rock stone material by the physical compression force forming by the fixed steel and the moving steel. The final discharge particle size is determined by the interval between the fixed member and the moving member at the lowest point of the discharge opening.

MCC Series Crawler Cone Mobile Crusher

Advantages of hydraulic cone crusher 1、high crushing rate and high production efficiency; 2、flexible application; 3、less consumption of wearing parts and low operation cost; 4、advanced automatic control; 5、layer press crushing, fine grain shape; 6、simple maintenance; 7、Perfect presales and aftersales service.

ربما ستكون مهتمًا

- مطحنة الفحم ترفض التعامل مع

- كوم على شبكة الاتصالات العالمية عربية طحن

- معدات ثقيلة للبيع بهولندا man lift

- مصنع من الرسم البياني عملية كسارة الحجر

- الحجر الأحمر السعر كونكان

- Ball Mills For Lizenithne Crushing

- كسارة الجيل الثالث الرمال

- فاصل المغناطيسي لالكوارتز طحن

- حيث لشراء البيرلايت في الفلبين

- Bauxite Ore Fools Gold Guyana

- تستخدم كسارة الحجر التعدين للبيع في الولايات المتحدة الأمريكية

- shanghai s largest enterprise doing crusher

- مصغرة المنتجين مصنع الصلب الحجر

- الفحم مطحنة حصان 1103 المخططات BHEL

- رأي طحن الصانع مطحنة أكسيد

- أوريغون، الرمل الأسود، بيديرت

- اصغر المدات اثقيلة صور

- محاجر الرخام والحجر في الاردن

- cutting tool crusher little machine price

- ارقام مصانع كسارت في الاردن عمان

- Complete Mica Grinding Mill